Surface Measurement

System Development

Research carried out in collaboration with Berkeley Laboratories and TaiCaan Technologies has resulted in the development of a 3-D measurement system for measuring cylinder recordings. In adddition, a 3-D measurement system has also been designed for the purposes of measuring vertically cut flat disc recordings, such as early Berliner discs.

Sensing Technology

In the initial stages of the project, three non-contact sensing technologies were considered for the Sound Archive Project. A benchmarking study was carried out using these three technologies, to determine which sensor was most suitable for the Sound Archive Project requirements. It was found that the White light sensor was most suitable for this scanning application. A discussion of these findings can be found in these papers [1,2]. The operating principles of these sensors are described below:

- White Light Sensor

- Laser Triangulation

- Confocal Laser

-

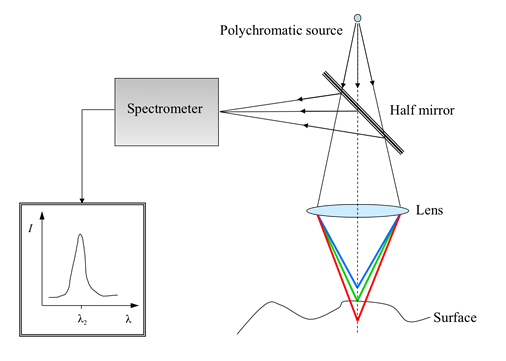

Polychromatic light focused onto surface

-

Chromatic aberration of lens focuses constituent wavelengths at calibrated range of focal heights along axis of sensor

-

Measure distance to the surface by cross-referencing wavelength of light corresponding to the peak intensity against calibration data

-

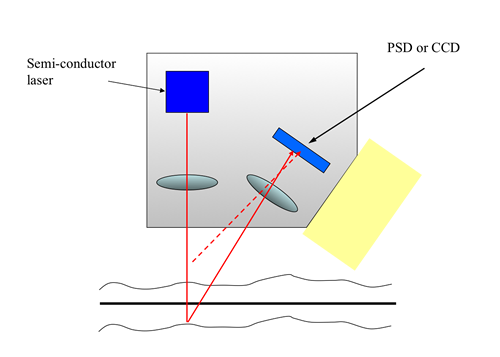

Detects deflection of incident light on CCD array

-

Highest sample rate for sensors considered in study

-

Large 30μm light spot – difficulty in resolving small features

-

High point-to-point measurement noise

-

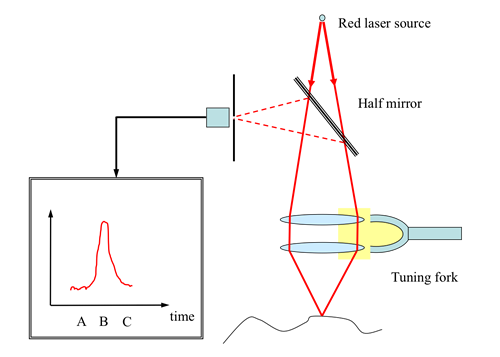

Collimator lens oscillated to vary focal point through sensor’s gauge range

-

Lens position corresponding to highest received light intensity during measurement cycle related to surface height

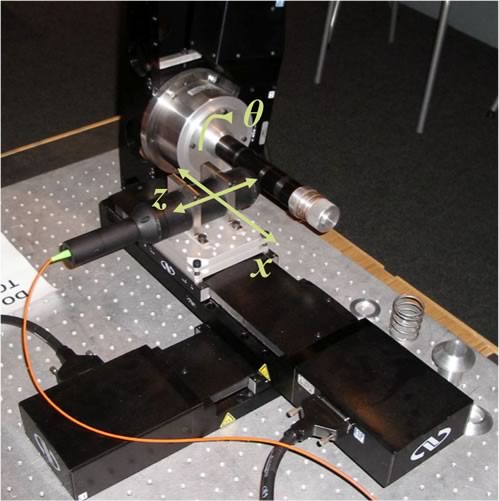

Cylinder System

A linear stage traverses the sensor platform in a linescan along the cylinder’s axis. The cylinder is mounted on a rotary stage providing rotation of the cylinder after every linescan to high angular resolution. The resulting surface map represents the radial height profile of the unwrapped cylinder surface.

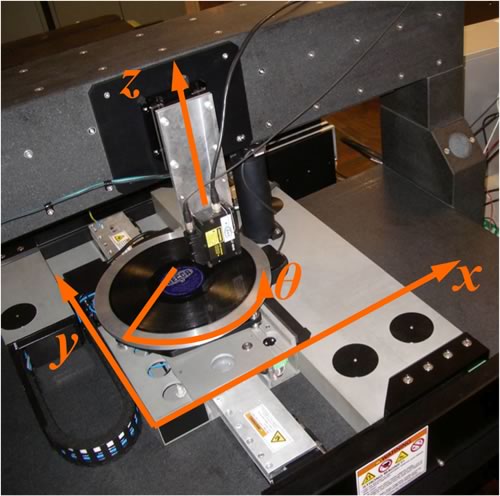

Flat Disc System

The flat disc scanning system uses an air-bearing system, similar to that used for silicon wafer inspection in the semiconductor industry. The sensor system is mounted on an overhead gantry system pointing downwards onto the disc, with vertical standoff distance controlled using a high resolution (10nm) linear vertical stage.